Luna Innovations’ Technology Recognized in Award-Winning Geotechnical Research

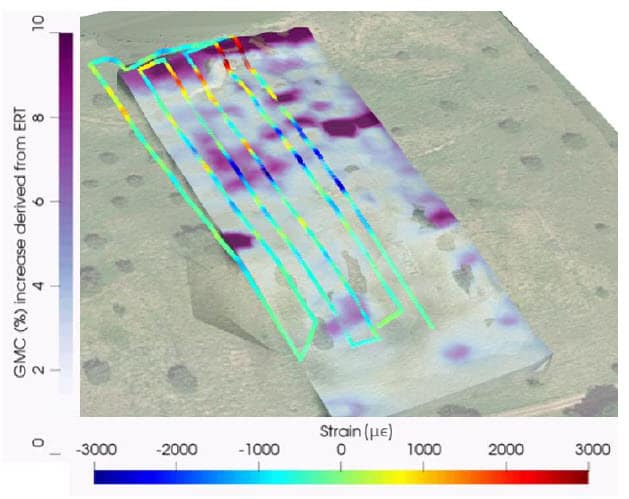

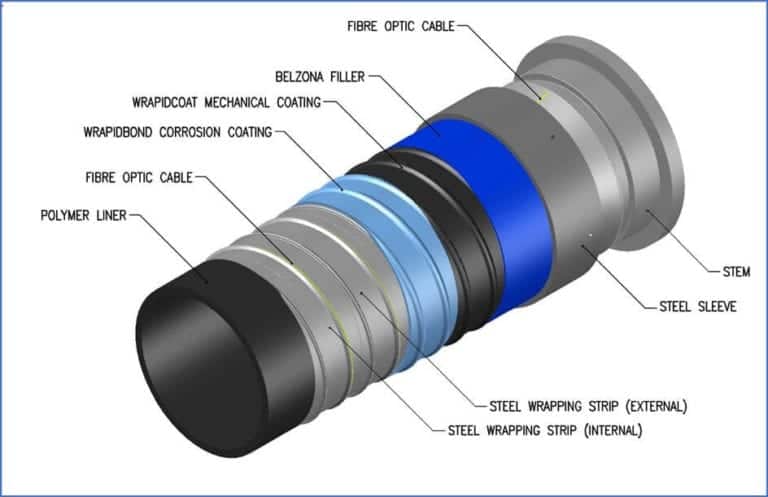

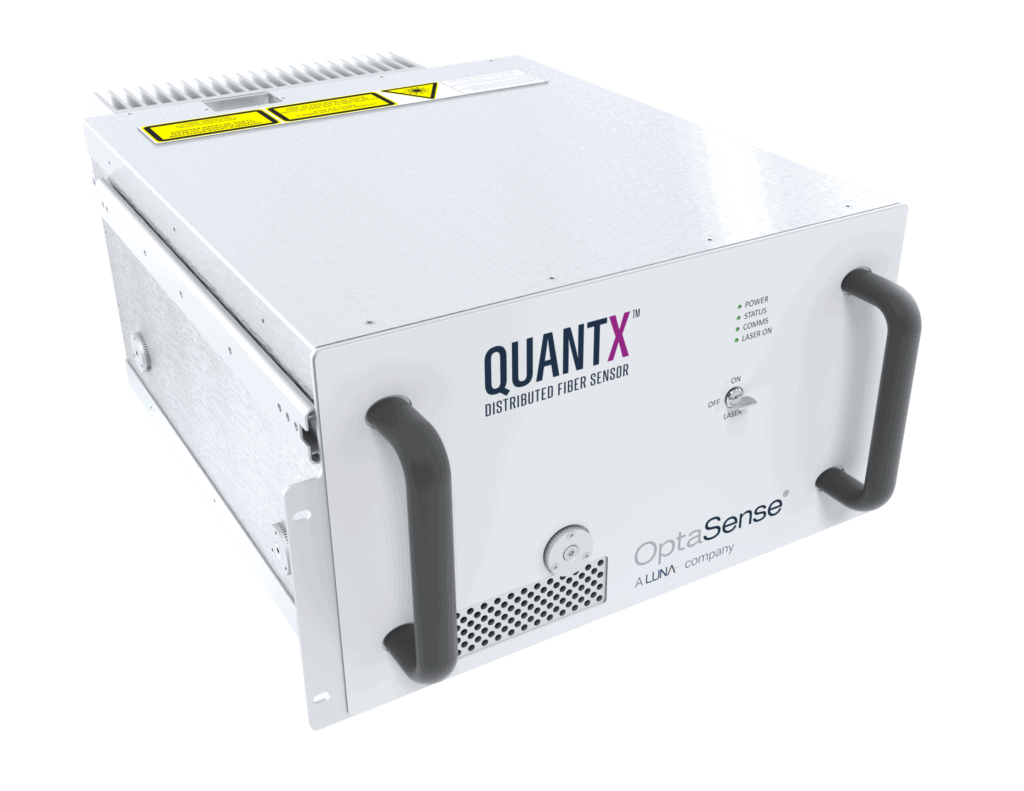

Luna Innovations’ Optical Systems Specialist Roger Crickmore was recently honored as a co-author of a research paper awarded the prestigious 2024 British Geotechnical Association (BGA) Medal. The award recognizes significant contributions to geotechnical engineering research […]

Luna Innovations’ Technology Recognized in Award-Winning Geotechnical Research Read More »