RESERVOIR MONITORING

Attain real-time acquisition and visualization of accurate well and reservoir performance data with borehole seismic evaluation services from OptaSense. Our reservoir monitoring services provide high quality information on reservoir stimulation and depletion efforts.

Reservoir Monitoring Services

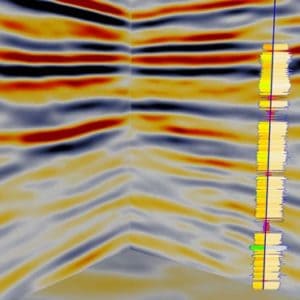

OptaSense Distributed Acoustic Sensing (DAS) Vertical Seismic Profiling (VSP) is a proven and cost-effective solution for accurately characterizing & developing a reservoir over the life of the field. A permanently installed fiber-optic cable in a well allows repeated 2D and 3D acquisition of high-quality seismic data with reduced rig time, little to no interruption in production, and no costly and precarious well intervention. Acquisition parameters are optimized in the field to provide the best-quality data for use in 2D and 3D imaging. Time-lapse imaging and characterization give our clients the best means to understand the effects of reservoir production, injection, compaction and to expand the field through new drilling prospects. OptaSense is a leader in acquiring multi-well 2D and 3D VSP acquisitions in record time and with fast data turn-around.

OptaSense 2D and 3D imaging and data processing services provide our clients with intelligent solutions for reservoir characterization. OptaSense also offers specialty services, such as virtual-source generation and interferometric imaging of VSP, microseismic and passive seismic data, as well as complex salt flank and unconventional reservoir imaging.

Rig Source and Zero Offset VSP

OptaSense DAS VSP provides optimal time-depth control as well as reflectivity needed to assess near wellbore seismic characteristics. In addition to baseline zero offset corridor and checkshot data, our time lapse analysis enables operators to delineate changes with respect to time. Rapid assessment of VSP data provides an immediate look at the effects of production and deformation surrounding instrumented assets.

OptaSense seismic services monitor any available fiber downhole, on surface or the ocean floor. Our high resolution and long range IU’s have interrogated fibers up to 100km. High-quality seismic data has been processed on its own for both deep and shallow imaging. In addition, fiber optic DAS has been integrated into conventional nodal surveys for joint imaging.

OptaSense fiber-optic monitoring services include surveillance of processes surrounding injector wells. Both in existing oil fields or as part of carbon capture storage and utilization, the monitoring of injector wells is a critical aspect as they could trigger induced seismic events. OptaSense’s real time Microseismic Monitoring Service has been deployed to assess injection processes as well as caprock integrity. Our high sensitivity systems have surpassed the performance and detection thresholds of conventional seismic networks while providing 24/7 surveillance at a fraction of the cost. Real-time assessment of induced seismic events provides operators with a critical tool to assess operational aspects of their assets.

Induced Seismicity For Geothermal Wells

Enhanced Geothermal Systems (EGS) are a clean source of renewable & sustainable energy production increasingly being employed around the world. EGS is no longer limited to areas with natural hydrothermal activity & sufficient rock permeability—geothermal energy can now be produced in hot dry rock via hydraulic stimulation & other methods. Understanding the geothermal reservoir is key to long-term energy production as well as expanding its capacity. OptaSense’s Distributed Acoustic Sensing (DAS) arrays are an effective and low-cost means to monitor induced seismicity during & after hydraulic stimulation & contributes to mapping the reservoir through time. Installing a permanent DAS array in EGS will be standard as geothermal energy production activity expands: OptaSense is the best choice for meeting the needs of a Clean Energy future.

OptaSense interrogators can measure seismic signals on fibers up to 100 Km in length. Available surface or downhole fibers can be utilized as densely sampled seismic arrays for regulatory compliance, early warning, and risk mitigation.

In addition to injector monitoring in instrumented fields, OptaSense’s Microseismic Service provides 24/7 surveillance for CO2 sequestration and wastewater injection monitoring.

High-resolution distributed sensing data is utilized to assess the effects of compaction and wellbore deformation. OptaSense’s interrogator units provide the highest sensitivity seismic measurements to assess 4D data from which subsidence effects are analyzed. The high-repeatability DAS measurements enable operators to track minute changes seen from instrumented wells. Using zero offset, 2D, or 3D geometries, the fiber data is used to illuminate various volumes surrounding the wells.

OptaSense services deliver cost-effective advanced monitoring solutions at all stages of a Carbon Sequestration project, including site evaluation, feasibility, borehole cementing, injection or capture and usage.

When performing Enhanced Oil Recovery operations, you want to sweep water, steam, or CO2 across your reservoir effectively and efficiently to push oil from injectors to producers. Conventional seismic imaging techniques often have infrequent and limited visibility of subsurface due to high cost and poor resolution, making flooding difficult to control and increased well spacing, by-passed reserves and early water or steam arrival become difficult to avoid. With introduction of OptaSense’s pioneering DAS VSP technology a high resolution, ultra low-cost imaging solution is now possible. Imagine an intelligent well and reservoir management system that fully connects field operations to the subsurface through rapid and frequent imaging surveys. Envision the ability to watch sweep dynamics and outcomes unfold in real-time. Envision proactive operational control, precise new well placement, and refined reservoir models. OptaSense DAS-VSP offers a complete EOR solution.

OptaSense DAS technology provides a unique view of aspects surrounding mining operations. Using fibers that are deployed on trenches, shafts, boreholes, and tailing dams, the high-sensitivity measurements provide an assessment of seismic activity. This activity can be associated to fault activation, collapse, rocks falls and other induced events that may be indicative of different activities in the mine.

OptaSense’s real-time Microseismic Service integrates data from the available fibers and turns it into seismic network from which surveillance is conducted. These same fibers are also used for geological characterization using seismic methods. Our Answer Products team has expertise in seismic imaging for high-resolution structural assessments like fault identification, void detection, identification of unstable areas. Seismic imaging using DAS VSP is used to characterize the physical properties of tailings dams via shallow boreholes.