SEISMIC ACQUISTION AND PROCESSING

Real-time seismic without geophones

Achieving higher rates of return begins with a clear understanding of the reservoir. OptaSense Oilfield Services’ seismic acquisition and processing offering provides repeatable, high resolution imaging of the reservoir in real time, without the need for well intervention.

Our seismic acquisition and processing services include 2D, 3D and 4D vertical seismic profiling (VSP) and microseismic data. Through the use of Distributed Acoustic Sensing (DAS), we provide accurate measurements of frequency, phase and amplitude along the entire length of the wellbore.

OptaSense technology alleviates common restrictions encountered with conventional downhole tools, including production downtime, wellbore integrity risk and restricted wellbore access. Data acquisition can be performed on any wellbore, even under extreme conditions such as high temperature, high pressure, or highly deviated wells.

OptaSense DAS technology can be permanently installed behind casing, semi-permanently installed on the production string or temporarily installed using wireline or coiled tubing. After installing the DAS fiber, there is no need for further wellbore interventions.

Even in deviated or restricted wellbores, where conventional geophones are unfeasible, OptaSense seismic acquisition services offer quality, repeat borehole seismic measurements, including simultaneous and time-lapse surveys, in a cost effective manner for the life of your asset without any loss of production from your wells.

Illuminate complex geological environments

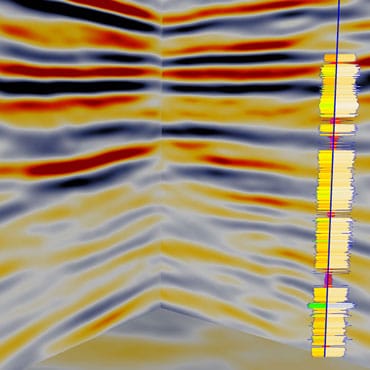

To reduce risk and optimize recovery, you need a clear picture of the reservoir. OptaSense Borehole Seismic Services help you illuminate complex geological environments by delivering superior data processing and imaging, complimented by a dedicated team of experts in borehole seismology.

Whether exploring challenging salt formations or developing unconventional reservoirs, we provide operators with the insight necessary to locate and produce hydrocarbons, safely and efficiently.

Our offering includes imaging and processing of vertical seismic profiling (VSP) and microseismic data. In addition to standard products, we offer specialty services, such as virtual source generation and interferometric imaging of VSP, microseismic and passive seismic data, which is used to solve complex salt flank or unconventional reservoir imaging.

For fast and accurate results, leverage our team of experts who have acquired decades of experience in borehole seismic processing and imaging. Using advanced algorithms combined with commercial and proprietary tools, they will provide quality data sets and subsurface images that reduce uncertainty, mitigate risk and optimize recovery.

SERVICES

Vertical Seismic Profiling

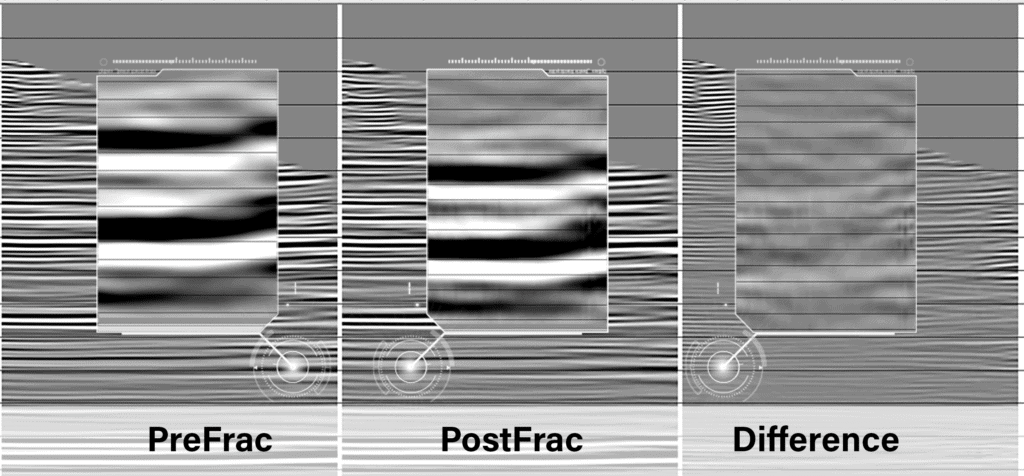

VERTICAL SEISMIC PROFILING Cost-effective, repeat acquisition OptaSense vertical seismic profiling (VSP) services provide accurate, repeat borehole seismic measurements that provide enhanced imaging of the reservoir, without the need for well intervention. With OptaSense VSP acquisition

Processing And Imaging

PROCESSING AND IMAGING Gain a Wealth of Knowledge With Superior Data Processing and Imaging Our offering includes imaging and processing of vertical seismic profiling (VSP) and microseismic data. In addition to standard products, we offer

Microseismic Processing

MICROSEISMIC PROCESSING Sub-seismic resolution measurements in real-time Distributed fiber-optic sensing is increasingly being used for microseismic monitoring and processing using fiber permanently installed on casing or temporarily deployed on wireline. Real-time microseismic processing in the

Microseismic Monitoring

MICROSEISMIC MONITORING SERVICE Fiber Optic Microseismic and Strain Determine Fracture Geometries OptaSense provides a unique solution for microseismic monitoring. Our fiber-optic interrogators allow for high fidelity microseismic monitoring in individual or multiple wells and can

Dedicated Expertise

DEDICATED EXPERTISE Rely on a team of dedicated experts With years of experience processing data from complex geological environments, our experts apply advanced algorithms and methods to solve complex processing and imaging challenges. The Team

Advanced Workflows

ADVANCED WORKFLOWS Overcome complex processing and imaging challenges Whether the goal is to optimize the acuisition geometry or predict the seismic response, we believe a successful VSP project starts with modeling. Success begins with a