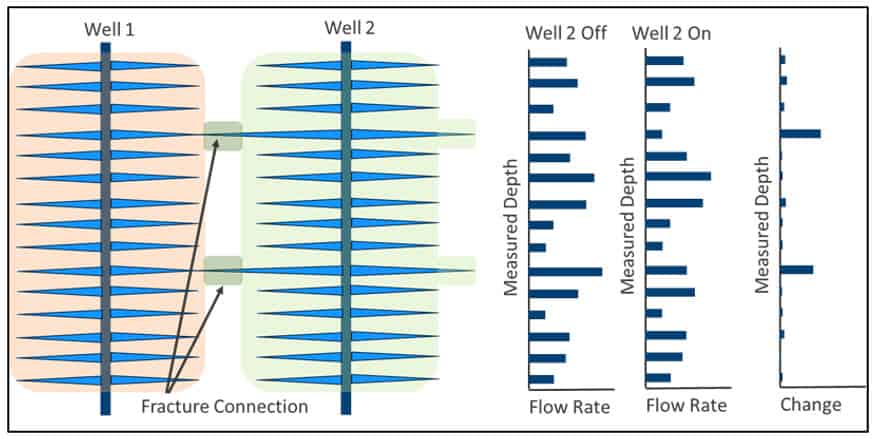

Production Monitoring

PRODUCTION MONITORING OptaSense production monitoring services add critical mass in your production efforts by allowing you to monitor in-flow along the production zone, artificial lift performance, and wellbore integrity for the life of your asset.