FRACTURE MONITORING

Optimize Wells to Improve Productivity and Reduce costs

Using optical fibers permanently installed behind the casing, OptaSense’s Oilfield Services utilizes advanced Distributed Acoustic Sensing technology and Distributed Temperature Sensing helps you confirm successful completion operations, determine fluid and proppant distribution and monitor cross well communications in real time, at the perforation level by acquiring continuous acoustic and temperature measurements along the length of your well. This service also allows you to measure well interference, such as strain and temperature, on multi-well pads when one or more wells are instrumented with a fiber-optic cable. As a result, the data can provide valuable information on future well placement, perforation designs and reservoir development.

Hydraulic Fracture Monitoring Service

- Perforation cluster efficiency and distribution of fluid and proppant

- Effectiveness of flow diversion

- Well integrity issues

- Initial flowback and well cleanout

- Long term production and reservoir performance

Ready to optimize fracture performance?

Monitor Completion Operations

On-demand completion data not only provides the insight you need to optimize fracture programs, additionally, it also allows you to mitigate operational issues in order to save completion dollars. For instance, to mitigate losses associated with mechanical failures, the Hydraulic Fracture Profiling service monitors all operations in real time, such as confirming perforations, plug setting, ball drops and sleeve actuation. It identifies unwanted inter-stage communication in treatment wells, as well as unwanted hydraulic connectivity in offset wells. Frac monitoring also enables the immediate detection and location of well integrity issues.

Visualize Crosswell Strain and Identify Frac Hits

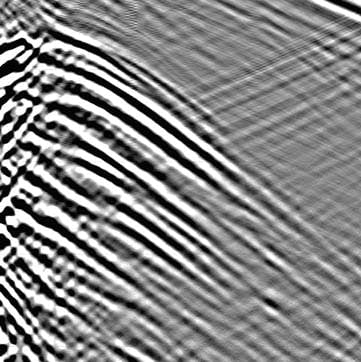

With picostrain and milikelvin temperature sensitivity, our fracture monitoring service provides real-time displays of crosswell strain and temperature communication to identify frac hits while fracturing. A frac hit occurs when a a well being fracked communicates with one or more nearby wells. A frac hit to an offset well (particularly mature wells) can be quite detrimental.

As a result, this capability measures minute deformations of the casing caused by changes in formation strain near the wellbore induced by fracturing neighboring un-fibered wells. This powerful data set can be integrated with microseismic, production logs, geology, and other data to optimize stimulation effectiveness, well spacing and reservoir development strategies. Above all, better understanding of fracture geometry from post-completion analysis can be used to calibrate hydraulic fracture models, improving future well and and completion design.

Visualize the Effectiveness of Your Completion

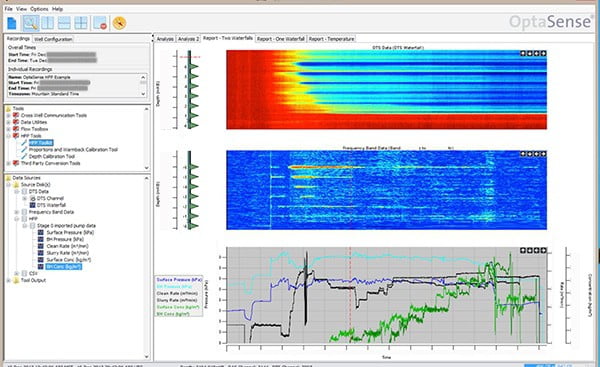

Dig deeper into hydraulic fracturing data with the OptaSense DxS Pro visualization software. This software program allows operators to integrate multiple data sets, analyze DAS and DTS response during treatment, and generate 4D animations. In addition, it offers easy-to-use data processing and conversion tools, as well as application-specific workflows

DID YOU KNOW

By permanently installing fiber behind the casing, OptaSense Distributed Fiber Optic Sensing (DFOS) allows you to acquire borehole seismic data, profile hydraulic fractures and monitor production flow in real time, for the life of your asset.