CASE STUDY

OptaSense Provides Crosswell Strain Data For Unconventional Reservoirs

Fiber-optic sensing delivers clearer picture of hydrocarbon resources

Problem:

- Unprofitable unconventional resources

- Single point measurements or snapshots

- Conflicting diagnostic tools

- Questionable geometry and orientation assessment

Solution:

- OptaSense Crosswell Strain Monitoring

- High resolution strain data

- Real time tracking of the fracture network formation

- Real time monitoring of operational aspects of the completions

Value Delivered:

- Better understanding of complex interactions

- Identification of stimulated reservoir zones and improved stage offsetting

- Determination of optimal completion design

- Identification of stage isolation issues

The Challenge

Developing a profitable unconventional resource with optimal access to hydrocarbons requires the most economical completions design and well placement strategy. Fractures from hydraulic fracturing are the vital arteries for hydrocarbons locked in the hosted rock to travel towards a well and be produced. As fundamental as creating fractures sounds, the ability to measure fracture growth, distribution and extend accurately and economically has lagged. Much of the difficulty is due to the deep buried location and available diagnostics. Those available today, even when combined collaboratively, lack one or more qualities of resolution, timely results, cost or tertiary measurement resulting in vague understanding of the fractured reservoir.

The optimization of well completion and well spacing is a complex task due to interdependencies of unconventional reservoirs. The choice of design has important consequences on the ultimate recovery of resources from the reservoir. Given that the completion design can result in different fracture networks it is important to have a tool that provides direct real time data regarding the fracture geometry. Furthermore, as different well designs stimulate the rocks differently it is important to have a cost-effective and unbiased look at the completion operation that is optimized to the properties of the rocks, reservoir fluids and resource layers being developed.

An operator in North America wanted to assess the performance of fundamental types of completions design and measure fracture geometry and distribution, but found it challenging to find a suitable and sensible method. The challenge to the operator was to determine which well design resulted in the most even distribution of fractures and hence the availability of hydrocarbon resources in the reservoir.

The Solution

In order to assess the performance of different completion designs the operator deployed fiber optic and measured strain signals. OptaSense’s DAS crosswell strain was measured and used as a tool to characterize the geometries of hydraulic fracs and to assess the far-field efficiencies of stimulation operations in unconventional reservoirs. DAS Strain measures the occurrence of perturbations due to the fracture propagation during hydraulic stimulation.

OptaSense monitored DAS strain in wells stimulated for a variety of completion systems: plug-and-perforating (PnP), open hole packer sleeves (OHPS), as well as, data from a well completed via both ball-activated cemented single point entry sleeves (Ba-cSPES) and coil-tubing activated cemented single point entry sleeves (CTa-cSPES). By measuring the strain fronts during stimulation from nearby offset wells, it was observed that most stimulated stages produced far-field strain gradient responses in the monitor well.

In this project, OptaSense have gathered DAS strain data from hundreds of stages over a variety of completion systems in multiple wells and pads. The crosswell strain data shows that:

Hydraulic fracs are planar, parallel and mostly contained within a well-defined Frac-Zone-Domain independent of the completion system used.

Deviations from the expected azimuth are mostly the result of well construction and stimulation defects.

Completion practices and frac placement impact both near-wellbore and far-field frac geometries.

Using OptaSense crosswell strain as a diagnostic has the unique advantage of high resolution measurements that are capable of delineating fractures from the smallest cluster designs that operators use. Flexibility in deployment including permanent fiber optic as well as hybrid wireline systems with conventional arrays further expands the opportunity for integrated studies of the stimulated reservoir.

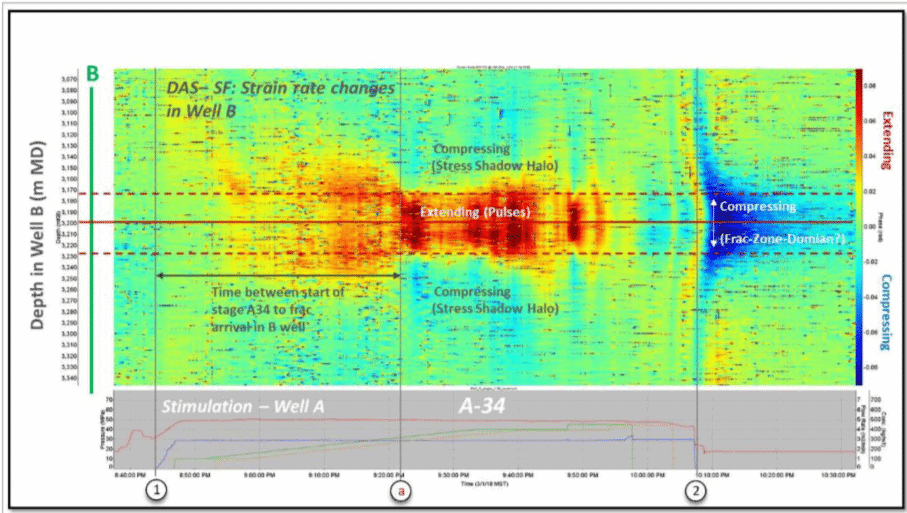

Annotated display of cross-well, DAS Strain Front of a single stage from nearby offset Well-A, stimulated via coil-tubing activated single point entry sleeve observed in a not-yet-stimulated monitoring Well-B instrumented with a fiber cable deployed behind casing. Stage A-34. The patterns along the fiber can be used to obtain a variety of information about frac geometry in the far-field such as high-resolution frac azimuth. (SPE 195943-MS)

Delivered Value

The strain monitoring has provided greater confidence in the fracture network assessment. The high resolution frac geometry information provided by DAS strain away from the wellbore has also enabled the operator to improve stage offsetting and well azimuth strategies. In addition, identifying the re-stimulation and loss of resource access that occurs with poor stage isolation also shows opportunities for improvement in future completion programs. This in turn, allow operators to optimize operational decisions to more effectively access the intended resource volumes. OptaSense’s services show how monitoring high-resolution deformation via fiber optic (FO) combined with the integration of other data can provide high confidence insights about stimulation efficiency, frac geometry and well construction defects not available via other means.

OptaSense DAS far-field strain and near-field direct acoustic measurements via FO in the well offers for the first time, the possibility of calibrating frac models by constraining the fracture network geometries derived from high resolution data from the stimulation of nearby offset wells. In addition, it allows model solutions with measurements of strain at multiple locations along the wellbore and more importantly at the surrounding wells.

The FO data was able to map the azimuth of hydraulic fracs and precisely determine a variety of far-field dimensions and properties such as frac-to-frac distances, FracZone-Domain widths, propagation speed, as well as, information about well construction effectiveness in real time. By using DAS Crosswell Strain measurements, the operator had a direct look at the fracture networks generated by different completion methods. Based on the strain the operator was ultimately able to determine a larger resource opportunity for a specific completion design.

For more information, please contact your OptaSense representative or visit optasense.com/oilfield-services/crosswell-strain-monitoring-service/